What is Tight Buffered Fibre?

Single-mode or multi-mode optical fiber with a tight jacket secondary coating structure is called tight jacket optical fiber or tight pack optical fiber, is in the bare fiber once coated optical fiber (UV fiber) on the direct secondary plastic (PVC/PVDF/LSZH/Hytrel) and other manufacturing, the outer diameter of the tight fiber is usually 0.6mm and 0.9mm two kinds of nominal, It is the basic component of manufacturing a variety of indoor optical cable, can also be used alone, compact fiber coated with various materials can be directly used as pigtail, which is used to connect all kinds of optical active or passive devices, instruments and terminal equipment.

How to Make Tight Buffered Fiber?

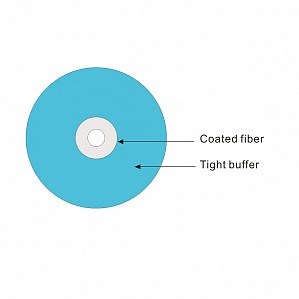

1.Tight Buffered Fiber structure

2.According to tight buffered fiber structure need three production line to make.

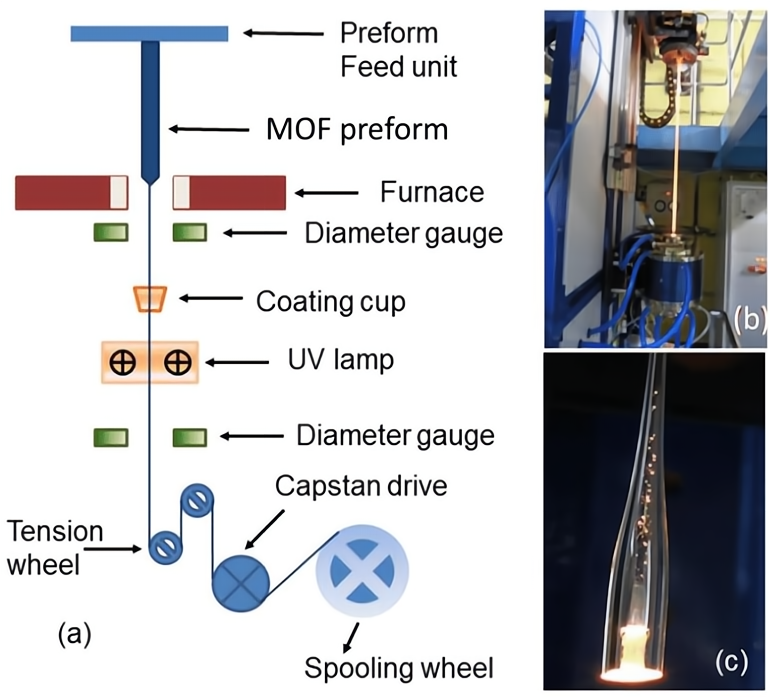

一、Draw tower

The optical fiber is obtained from a multi-layer, pure glass cylinder, called the preform. This large tube (generally 20 cm around and 2 m high) is set vertically at the top of a metal tower. Because the final glass fiber is obtained by “drawing” down a droplet, it is commonly called the draw tower.

二、Fiber Coloring and Rewinding Machine

FBK-1800 fiber coloring rewinding machine is mainly used for full color chromatographic coloring of SM and MM fibers, which is convenient for identification of multiple fibers in the PBT fiber tube or micron cables. At the same time, the device can also be used for rewinding segmentation of optical fibers.

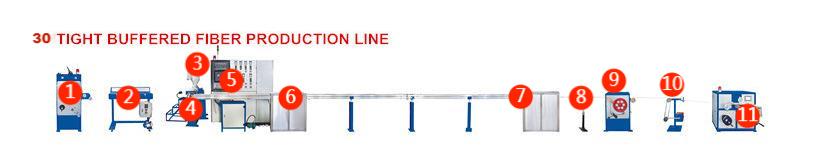

三、30mm Tight Buffered Fiber Production Line

This Optical fiber cable production line makes fiber optic cable buffer 0.6/0.8/0.9mm. Cable structure: bare fiber + LSZH/PVC sheath, and other similar cables.

Line configuration

Two heads fiber motorized pay-off;

Fiber Preheating oven;

25KG dryer and hopper

30 Extruder;

PLC+IPC electricity control cabinet;

Movable water trough and warm water tank;

Cooling water trough and water tank;

Ink-jet printer stand device without ink-jet printer;

¢400mm wheel capstan;

Tension unit;

Take up machine (automatically switching take-up option available).

Contact: Mrs.YoYo

Phone: +86-13902307496

Tel: +86-0769-86298298

Email: yoyo@fibercablemachine.com

Add: Jinhui Building, No. 68 zhongtang Section, Guansui Road, Zhongtang Town, Dongguan City, Guangdong Province)