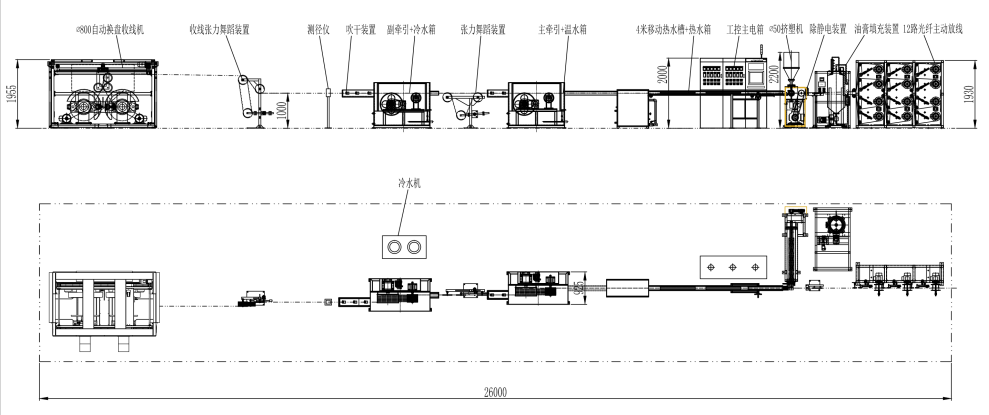

Structure speed: 800m/min; Processing speed: about 600m/min(1.8mm PBT loose tube) Pay-off number: 12; Take-up reel size: φ800mm Length of production line: ≤35m Power supply request: 70KVA, AC380V ±10% 50HZ three-phase five-wire Power consume: about 40KW/h

This fiber secondary coating line is used for extruding 1~12/24 core optical fiber loose tube, the jacketing material is PBT, loose tube is round and smooth surface, its dimeter is uniform.

A. The optical fiber pay-off is the motorzed pay-off device, the tension of the pay-off line is stable and reliable, and the tension is adjustable.

B. The extruder adopts special screw, which has good extrusion linearity and high extrusion efficiency.

C Jelly filling device has professional de-bubble effect, euipped with precision metering pump and a precision weighing device to ensure timely replenishment of ointment.

D·Take-up is double reels automatic changed without deceleration, and high production efficiency.

E. International industrial computer technology control system with high degree of automation, it can be linked with MES, ERP systems, real time tracking and managing production..

F .The main control systems and components are international famous brands, and the production line has high stability and reliability.

| Extruder type | 50×25 Extruder |

| extrusion material | PBT |

| structure speed | Max.800m/min |

|

production speed |

Max.500m/min

(1.8mm PBT loose tube) |

| No of optical fiber pay-off reels | 12 |

| Specification of optical fiber pay-off reels | 25km and 50km standard optical fiber reels |

| Pay-off tension of optical fiber | 0.4N-1.5N |

| Take-up reels Specification | PN630reel and PN800 reel |

| excess loss after extrusion |

≤ 0.02db / km (sm fiber@ 1310nm, 1550nm) |

| Center height of machine | 1000mm from background |

| Items | Qty. |

| 12heads fiber pay off | 1set |

| Electrostatic device removed | 1set |

|

Jelly filling device |

1set |

| 50 extruder | 1set |

| Dryer +hopper 50kg | 1set |

| IPC+PLC program control systerm | 1set |

|

Movable water trough with hot water tank |

2sets |

|

Capstan |

1set |

|

Fixed water trough with cooling water tank and blower+Industrial chiller |

1set |

| laser diameter gauge | 1set |

| Auxiliary tractor | 1set |

|

Vertical accumulator |

1set |

|

dual-shaft take-up 630-800mm |

1set |

Contact: Mrs.YoYo

Phone: +86-13902307496

Tel: +86-0769-86298298

Email: yoyo@fibercablemachine.com

Add: Jinhui Building, No. 68 zhongtang Section, Guansui Road, Zhongtang Town, Dongguan City, Guangdong Province)