1. Structure speed: 1800m/min. 2. take-up tension; 0.3N-1.2N. 3. take-up /pay-off reel sizes: φ235mm * φ155mm * 25.4mm (outer diameter * inner diameter * shaft hole). Φ265mm*φ165mm*25.4mm (outer diameter * inner diameter * shaft hole). 5. additional loss: ≤ 0.02db / km (sm fiber). 6. equipment size: 2.1m * 1.5m * 1.9m (L * W * H). 7. power supply requirements: ~AC380V ±10% 50HZ three-phase five-wire. 8. the total power supply: ≈ 13KW. 9. Normal running power is about 6KW/h. 10. Colorin

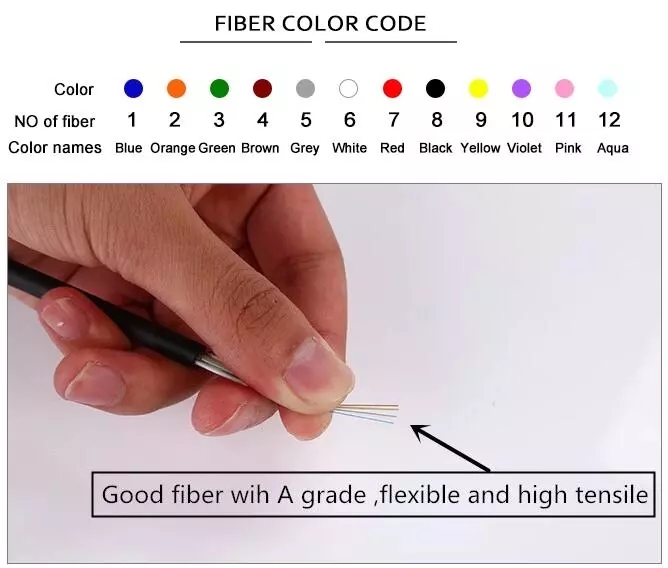

fiber coloring rewinding machine is mainly used for full color chromatographic coloring of SM and MM fibers, which is convenient for identification of multiple fibers in the PBT fiber tube or micron cables. At the same time, the device can also be used for rewinding segmentation of optical fibers.

Famous international brand UV curing oven is used to effectively improve the curing effect of bare optical fiber coloring. The equipment is controlled by Siemens 300 series PLC, with high automation and can operate multiple devices by one person.

|

Optical fiber number |

1 |

|

Structure speed |

≤1200m/min |

|

Coloring speed |

≤1000m/min |

|

Rewinding speed |

≤1200m/min |

|

Thickness of coloring layer |

3-5μm |

|

Pay-off tension |

0.4N-1.2N±0.05N |

|

Take-up tension |

0.4N-1.2N±0.05N |

|

Traversing pitch |

0.1-1.0mm±0.01mm |

|

Extra-attenuation after coloring |

≤0.02dB/Km(SM , 1500Nm) |

|

Optical fiber reel size (max.) |

25km/50km reel weight 10kg |

|

Nitrogen purity |

≥99.99% |

|

Compressed air |

0.5mpa |

|

Items |

Qty. |

|

Movable optical fiber pay-off unit |

1set |

|

Fiber coloring and material supply system |

1set |

|

UV curing oven |

1set |

|

Capstan and counter unit |

1set |

|

ake-up and traversing unit |

1set |

|

Electric control system and software |

1set |

|

Air fan |

1set |

Contact: Mrs.YoYo

Phone: +86-13902307496

Tel: +86-0769-86298298

Email: yoyo@fibercablemachine.com

Add: Jinhui Building, No. 68 zhongtang Section, Guansui Road, Zhongtang Town, Dongguan City, Guangdong Province)